Automatic printing machine heater

Automatic printing machine heater Specification

- Temperature

- 0C to 400C adjustable

- Heat Source

- Electric

- Power Consumption

- Approx. 3 kWh

- Power

- 3 kW

- Fuel Type

- N/A (Electric Powered)

- Material

- Stainless Steel & Aluminum

- Voltage

- 220V / 380V (as per model)

- Technology

- Automatic PID Controlled Heating

- Dimension (L*W*H)

- 600 mm x 200 mm x 80 mm

- Application

- Suitable for screen, offset, flexo and other printing machines

- Mounting Type

- Bolt-on / Clamp-on design

- Safety Features

- Overheat protection, insulated wiring, earthing provided

- Heating Element Type

- High quality Nickel-Chromium wire

- Insulation

- Ceramic fiber insulated for efficient heat retention

- Color

- Metallic Gray

- Weight

- Approx. 6 kg

- Control Panel

- Digital temperature controller with display

- Response Time

- Rapid heating, under 5 minutes to reach set temperature

Automatic printing machine heater Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- LUDHIANA

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 2 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- bubble Wrap

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001: Quality Management System Certification MSME Registration Certificate

About Automatic printing machine heater

Precision and Efficiency for Automatic Printing: Heater Flasher at Its Best

Enhance your automatic printing machine's efficiency with the Heater Flasher by Ambay Machine. Specifically designed to deliver precision heating, this innovative device ensures that ink cures evenly and quickly, reducing production time and preventing smudges or inconsistencies. Ideal for high-volume production environments, this heater flasher optimizes the curing process, keeping up with the speed and quality demands of automated systems. With consistent, even heat distribution, you can guarantee that your prints meet the highest standards of quality.

Advanced Temperature Control for Reliable Printing Performance

Experience reliability with the Heater Flasher's advanced temperature control system. Its equipped with precise temperature settings to adapt to various types of fabric and printing requirements, ensuring every print turns out flawless. With adjustable heating parameters, the Heater Flasher can be fine-tuned for different print media, offering versatility and control that print shops need. Achieve bright, durable prints on every material, knowing the heating process is completely optimized for outstanding outcomes.

Cost-Effective Heating Solution for Maximum Productivity

The Ambay Machine Heater Flasher isn't just about efficiency and quality; it also provides a cost-effective solution to improve productivity. The reduced curing times mean you can take on more orders and increase throughput, maximizing profits without compromising on print quality. Built with energy-saving features, the heater flasher keeps operational costs low while delivering the performance needed for large-scale printing. Make the most out of your printing setup, drive productivity, and enhance customer satisfaction with this premium addition to your automated printing line.

Advanced Heating Technology

This heater leverages a high-grade Nickel-Chromium wire for its heating element, surrounded by ceramic fiber insulation. This combination ensures both efficiency in energy use and rapid attainment of operating temperatures, with the added benefit of minimal heat loss to the surroundings. Designed for robust reliability and low maintenance, it is ideal for continuous industrial operations.

User-Friendly Digital Controls

Equipped with a digital temperature controller and clear display, the heater enables precise temperature adjustments from 0C up to 400C. The automatic PID control technology assures consistent heating and operational accuracy, enhancing quality and productivity in print applications.

Safety and Durability Built-In

Constructed from premium stainless steel and aluminum, the heater resists wear from high-heat use. Safety features like overheat protection, insulated wiring, and earthing provide peace of mind. The bolt-on or clamp-on mounting system facilitates secure installation and easy maintenance.

FAQ's of Automatic printing machine heater:

Q: How is the Automatic Printing Machine Heater installed on printing equipment?

A: This heater is designed for straightforward installation using a bolt-on or clamp-on system. It can be securely attached to suitable areas of screen, offset, flexo, and other compatible printing machines, ensuring efficient heat transfer and stable operation.Q: What process does the heater use for rapid temperature control?

A: Utilizing an advanced automatic PID-controlled heating technology, the equipment ensures precise and rapid temperature adjustments. The high-quality Nickel-Chromium wire heats up quickly, and ceramic fiber insulation retains heat effectively, allowing the unit to reach set temperatures in under five minutes.Q: When should the heating element or insulation be replaced?

A: Routine inspection is recommended, especially during scheduled maintenance. While the high-quality materials ensure long service life, any signs of wear, reduced efficiency, or physical damage (such as cracks in the insulation or inconsistent heating) indicate the need for replacement to maintain performance and safety.Q: Where is this heater most beneficial in the printing process?

A: The heater excels in any segment of the printing process requiring consistent and controlled heat, including ink drying and substrate pre-heating. Its rapid heating and stable temperature control improve print quality across screen, offset, and flexo applications.Q: What safety features are included with this heater?

A: Safety measures include overheat protection, fully insulated wiring, and an earthing mechanism to safeguard operators and equipment. The robust stainless steel and aluminum construction further enhances operational safety.Q: How does the digital temperature controller benefit operations?

A: The digital controller allows precise adjustment of the heater within a temperature range of 0C to 400C, displaying real-time temperature values. This ensures optimal settings are maintained for different substrates, reducing errors and maximizing printing consistency.Q: What advantages does electric heating offer over fuel-based alternatives?

A: Electric heating through Nickel-Chromium elements ensures clean and consistent energy delivery, eliminates fumes, supports easier maintenance, and provides exact temperature control, reducing overhead and improving energy efficiency in print environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Dryers Category

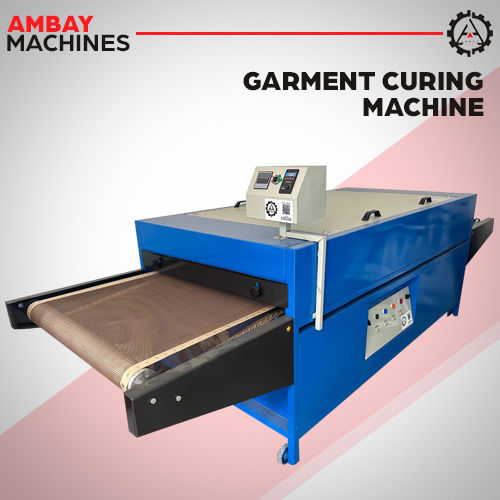

Garment curing machine

Price 155000.0 INR / Thousand

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Dimension (L*W*H) : 41472 Inch (in)

Technology : automatic

Weight : 700 Kilograms (kg)

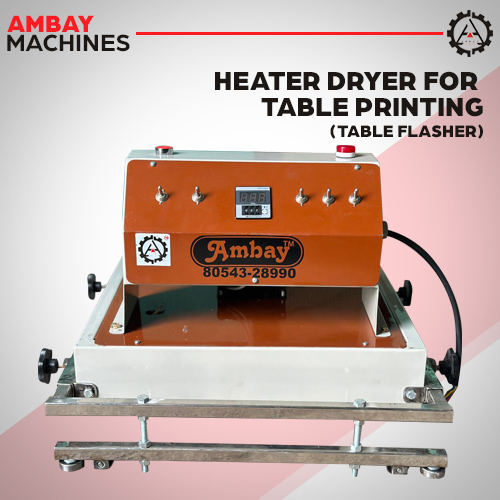

Table/Portable Flasher Curing & Drying Machine

Price 25000 INR / Unit

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Dimension (L*W*H) : 5184 Inch (in)

Technology : Semi automatic

Weight : 10 Kilograms (kg)

Send Inquiry

Send Inquiry Send SMS

Send SMS